If you’re overseeing new construction, you might wonder about the role of a blower door test. Simply put, this test measures a building’s air tightness, which is essential for energy efficiency and code compliance. Our comprehensive guide will walk you through why a blower door test new construction should be an integral part of your project, delivering insights for improved energy performance and regulations adherence, without divulging all the specifics just yet.

Key Takeaways

- Blower door tests are critical in assessing and ensuring the airtightness of new constructions, directly influencing the building’s energy efficiency, indoor air quality, and identifying areas that need air sealing.

- The blower door test involves preparing the site, executing the test with specific equipment, and then analyzing the results to identify air leaks and assess the air tightness of the building against set benchmarks.

- Proper timing of blower door tests during construction phases, adherence to building codes such as IECC for air tightness, and the use of both traditional and advanced air sealing techniques are vital factors in constructing energy-efficient buildings.

Understanding Blower Door Tests in New Builds

A blower door test serves as a diagnostic tool in building science, assessing the air tightness of a structure. It identifies the rate of air leakage, thus enabling us to pinpoint the areas that require effective air sealing. The importance of this test is two-fold; it not only ensures the integrity of the air control layer but also contributes to establishing the energy efficiency and indoor air quality of a building from the outset.

Early detection of air leaks through a blower door test offers several benefits:

- It paves the way for potential energy savings.

- It ensures that the building’s envelope is effectively sealed, maintaining optimal air pressure.

- It contributes to overall energy efficiency.

- It minimizes air leakage, resulting in a draught-free building envelope, which is crucial for maintaining energy efficiency throughout the building process.

The Role of Blower Door Testing in Air Sealing Strategy

Blower door testing is instrumental in boosting energy efficiency and reducing air leakage. It impacts the overall air sealing strategy by identifying specific leak areas, enabling targeted sealing to enhance energy efficiency. This process plays a pivotal role in developing an efficient air-sealing strategy that is essential for the energy efficiency of new constructions, such as:

- where warm air is leaking from the building

- where cold air is infiltrating the building

- where there are gaps or cracks in the building envelope

- where there are issues with insulation

By conducting blower door testing, you can identify these problem areas and take the necessary steps to improve energy efficiency and reduce air leakage.

Test data proves valuable in pinpointing problematic areas and gauging the severity of air leakage. With this information at hand, we can create precise and effective air sealing strategies, including the proper placement of required combustion air vent for a sealed combustion water heater.

Identifying and Addressing Air Leaks Early On

Air leaks can manifest in different ways, including warm air leaking and:

- Drafts or cold spots near windows and doors

- Elevated energy expenses

- Challenges in maintaining a steady temperature

- Audible sounds emanating from windows and doors

These leaks are predominantly found in the attic and basement areas of new constructions.

Addressing these leaks involves the use of different tools and techniques, including thermal and ultrasonic leak detectors, smoke tests, and visual inspections for cracks and gaps. Using techniques such as caulking around windows can help reduce air movement and control leakage, ultimately enhancing the energy efficiency of the home.

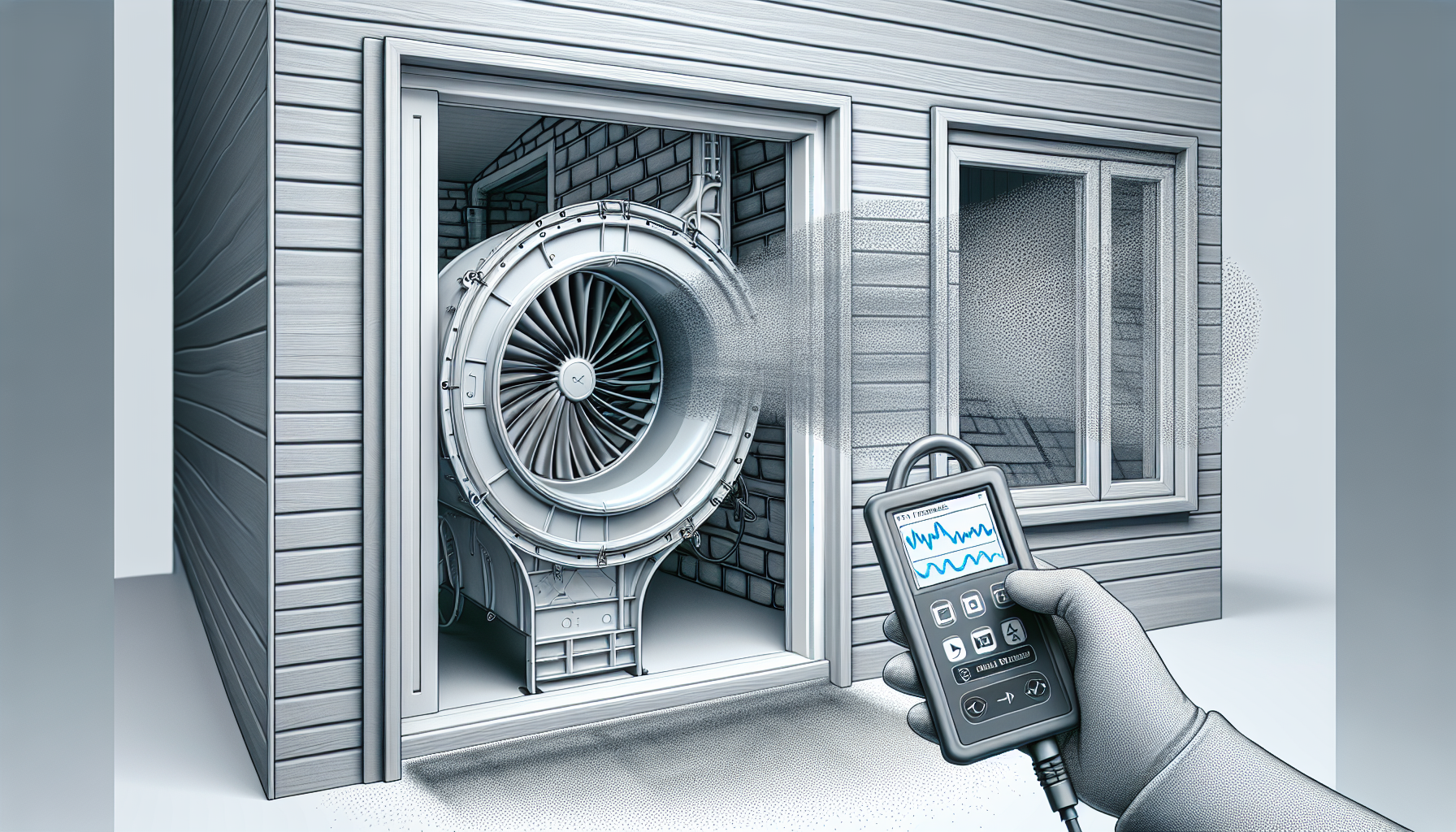

The Step-by-Step Process of a Blower Door Test

Understanding the significance of a blower door test is one aspect, but how is it actually conducted? The essential equipment needed includes a blower door, duct blasters, digital pressure gauges and other necessary tools. The initial preparations at a construction site involve closing all windows, opening all interior doors, and turning off any HVAC systems and appliances that might interfere with the test.

After this, the blower door test is set up. This involves:

- Closing and locking all windows and doors, except for the main entry

- Leaving interior doors open to allow airflow

- Assembling and adjusting the blower door’s aluminum frame to fit the entryway.

Preparing Your Construction Site for the Test

Preparing for a blower door test involves more than just the basic setup. It includes:

- Ensuring that all open-flame sources are extinguished

- Closing dampers

- Creating an airflow path

- Ensuring that doors and windows are closed

These steps are necessary to conduct a thorough assessment of air leaks and ascertain the building’s air leakage rate.

A review of HVAC equipment is also crucial to ensure proper sizing, installation, and effective operation, which directly affects the outcomes of a blower door test. Unfinished areas, openings, planned doors, windows, ducts, and vents should be appropriately sealed or accounted for as their status can impact the readings of the blower door test.

Executing the Blower Door Test

With the site prepared, the blower door test can commence. The necessary tools include a blower door, duct blasters, digital pressure gauges, and other equipment. The setup involves assembling and sizing the aluminum frame for the opening, connecting the frame to the door opening, setting up the blower door, initiating the fan to modify the house pressure by 50 Pascals, and documenting the outcomes for subsequent evaluation.

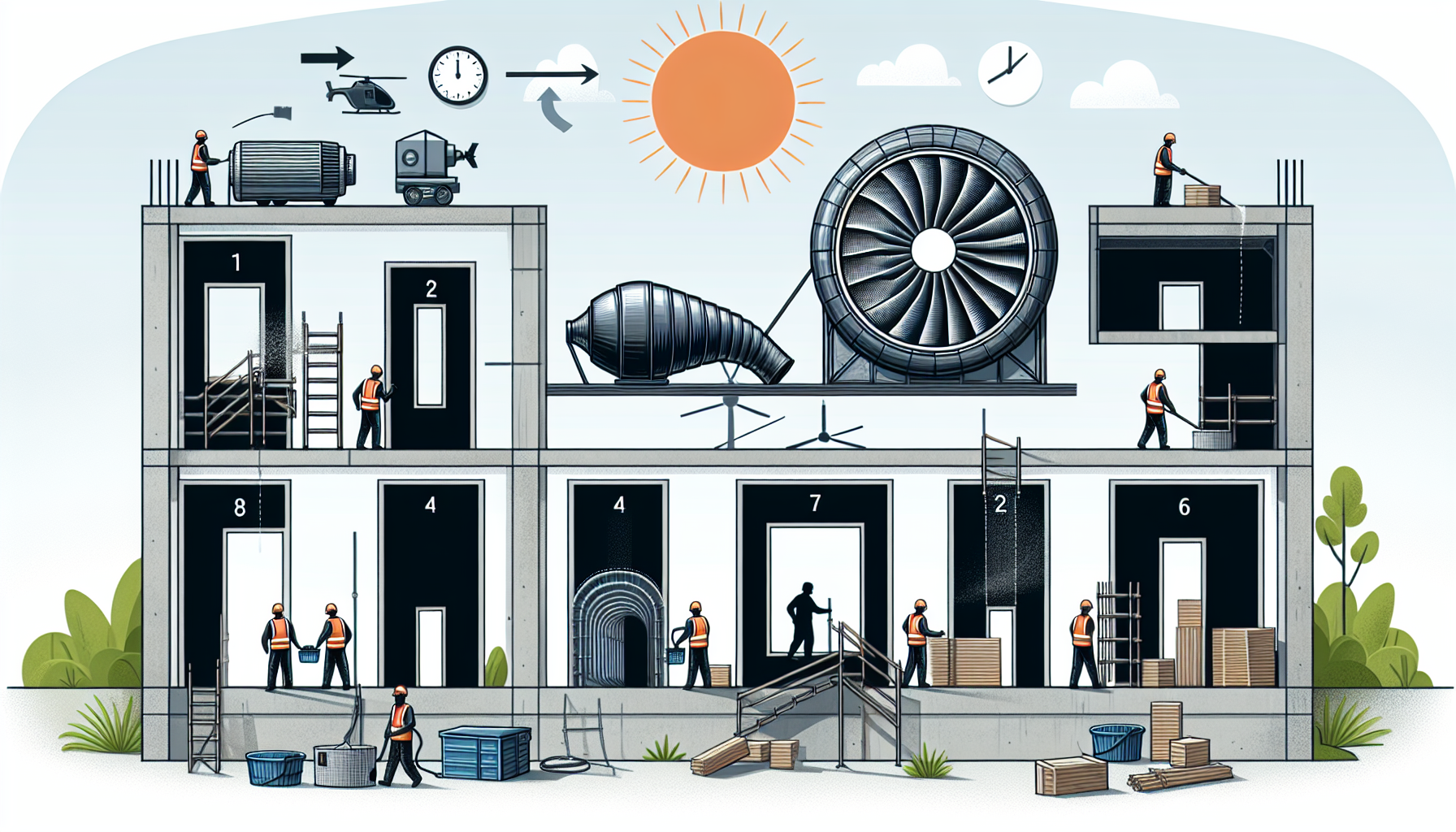

The specific procedures for conducting a blower door test involve:

- Closing all windows

- Opening interior doors

- Shutting exterior doors

- Turning off HVAC systems

- Mounting the blower door

- Connecting equipment

- Either pressurizing or depressurizing the building

- Measuring airflow and pressure

- Identifying leaks

- Evaluating the results to enhance air tightness and energy efficiency

The whole process of a blower door test typically takes about 25 to 35 minutes.

Analyzing Test Data for Optimal Air Tightness

Post-test, the data needs analysis. The building is pressurized or depressurized to a specific pressure, typically 50 pascals, to assess the level of airtightness. A common comparative metric involves ensuring that the blower door number, measured in cubic feet per minute, is less than or equal to the square footage of the home.

The analysis of blower door test data allows home energy professionals to:

- Identify specific areas of air infiltration and exfiltration in a home

- Locate and address air leaks

- Result in a substantial improvement in the building’s energy efficiency

However, it’s crucial to be mindful of common errors when analyzing blower door test data to avoid misinterpretation of results.

Timing Your First Blower Door Test: When is Best?

The scheduling of your initial blower door test can significantly impact the success of your air sealing approach. It’s recommended to schedule the first blower door test to coincide with the earliest feasible phase in which the envelope and all penetrations are sealed, typically during the drywall stage of construction.

However, there’s also an argument for conducting the blower door test towards the completion stage, after the paint is applied and final doors are installed. It’s also advisable to consider performing a mid-build test after the installation of MEP (mechanical, electrical, and plumbing) systems.

Compliance with Building Codes and IECC Requirements

Harmonizing your new build with building code compliance, including the International Energy Conservation Code (IECC) air tightness requirements, is essential for erecting a responsible and efficient structure. These building codes concerning air leakage testing in new constructions encompass ACH 50 standards, with distinct requirements based on the climate zone.

To ensure adherence to these air tightness building codes, a blower door test is conducted at a pressure of 50 Pa. The findings of the test are then recorded in a written report, which is submitted to the relevant building official for validation. Non-compliance with these codes may lead to penalties, fines, and potential criminal charges. Thus, it’s essential to stay updated with the most recent building codes and IECC requirements.

Advanced Techniques for Air Sealing in New Construction

What if your building doesn’t align with traditional designs? Advanced air sealing techniques can help improve energy efficiency in such cases. These techniques have a positive impact on energy efficiency in new buildings by minimizing air leakage, resulting in substantial energy savings and improved building performance.

Advanced air sealing methods, such as:

- AeroBarrier that distributes a caulk fog under pressure to air seal leaks

- the use of thermal detectors

- advanced air flow controls for forced air heating system

- ventilation controls

are some examples of techniques applied in constructions with unusual designs to ensure effective air sealing.

Sealing Complex Structures and Unusual Designs

Complex building structures present their own unique set of challenges. These challenges stem from the need for meticulous planning, attention to detail, and the use of appropriate sealing techniques. This is due to the presence of unique features, irregular shapes, multiple levels, intricate details, and numerous penetrations such as windows, doors, and utility openings.

Enhancing the effectiveness of air sealing in unusual or unique building designs can be accomplished by:

- Utilizing caulking or spray foam to seal gaps, especially around pipes and framing

- Upgrading insulation

- Ensuring proper sealing around windows to prevent outdoor air from infiltrating the interior

This process can be further influenced by the building materials used and the architectural design of the building.

Enhancing Traditional Methods with Modern Solutions

While the traditional air sealing methods have proven effective, modern solutions offer a more continuous air barrier and employ precise and skilled techniques. This results in a more comprehensive air sealing strategy, leading to reduced leakage and improved energy efficiency.

Conventional techniques for air sealing in buildings include the use of spray applied insulation materials like fiberglass, rock wool, cellulose, and foam, in addition to caulking or spray foam to seal between pipes and framing. The integration of these traditional methods with modern air sealing solutions has proven to significantly mitigate air leakage, ensuring airtightness, and minimizing energy losses in the building envelope.

Tools and Professionals: Who Should Conduct Your Blower Door Test?

Selecting appropriate tools and skilled professionals for the blower door test is of paramount importance. The necessary equipment includes:

- Blower doors

- Duct blasters

- Digital pressure gauges

- Potentially other tools

Noteworthy manufacturers providing these tools are TEC Minneapolis and Retrotec.

It’s also important to consider the qualifications and certifications of the professionals conducting the test. These professionals typically have certifications such as HERS Rater, BPI-Building Analyst, or IDL certification, which demonstrate their expertise and accuracy in performing blower door tests. When selecting a professional for a blower door test, it is important to consider individuals with relevant certifications and specific questions about blower door systems.

Ensuring Indoor Air Quality Alongside Air Tightness

Although air tightness is pivotal, maintaining the indoor air quality of your building holds equal significance. It’s important to balance increased air tightness with strategies to maintain adequate indoor air quality.

Preserving high indoor air quality in tightly sealed buildings can be accomplished through:

- careful consideration of ventilation systems

- selection of building materials with low VOC emissions

- potentially incorporating air cleaning devices

- the use of energy recovery or heat recovery ventilators to aid in refreshing indoor air while minimizing energy loss.

Furthermore, collaboration with HVAC professionals during the design phase can ensure a delicate balance between air tightness and proper ventilation.

Cost-Benefit Analysis: Saving Money with Effective Air Sealing

Efficient air sealing measures can result in homeowners saving an average of 15% on heating and cooling costs, contributing to an overall energy cost reduction of about 11%. The estimated cost to address air leaks in a newly constructed home is approximately $3600, which may result in an average of 15% savings on annual heating and cooling expenses.

Not only does efficient air sealing save you money on energy costs, but it can also:

- Elevate the property value of a new build through its ability to enhance energy efficiency

- Lower operational expenses

- Improve the overall comfort for the inhabitants.

Summary

In conclusion, conducting a blower door test in new constructions is an essential and cost-effective way to ensure energy efficiency. By identifying and addressing air leaks early on, you can save on energy costs and create a comfortable living environment. With the right tools, professionals, and a good understanding of air tightness, you can make informed decisions that can save you money in the long run and contribute to a sustainable future.

Frequently Asked Questions

How hard is it to pass a blower door test?

Passing a blower door test can be challenging, as an estimated 50% of newly constructed homes fail the test due to a lack of understanding of how to create a continuous air barrier system.

Are blower door test required?

Yes, blower door tests are required in most of the United States as a new construction code requirement. It is beneficial for builders to watch the process to improve their construction processes for future builds.

What is a good blower door test score?

A good blower door test score varies depending on the age of the home, insulation levels, and the condition of windows and doors. Generally, a new home should test less than 3.5 ACH50 for optimal airtightness.

What is the average cost of a blower door test?

The average cost of a blower door test done by a professional for an average sized house is approximately $300-$400. There is also an option to perform the testing on your own, with more professionals choosing to do them in-house.

What is a blower door test and why is it important?

A blower door test measures the air tightness of a building and helps identify areas in need of air sealing. It’s crucial for ensuring the energy efficiency and indoor air quality of a building.